What parameters affect the printing of resin models?

Digital orthodontics has brought with it the introduction of the 3D printers in the dental sector. These printers can be used for different purposes: printing models with which to manufacture aligners on them, printing retainers or even, as we have recently seen at a congress, printing the aligners directly.

To ensure the fit of any device we are going to make, the printed resin model must be as accurate as possible. So let's first defines what is precision. Applied to the world of 3D printing, precision is known as the reliability of a printer to reproduce the same model repeatedly with as little variation as possible between them. Precision is not the same as accuracy, which is more related to the detail of the print. Depending on the purpose of the device we are going to manufacture, it will demand a higher or lower precision/accuracy. For example, the impression of a retainer, which is an element to hold the teeth, will not demand the same accuracy as resin models used to make aligners to move the teeth.

¿How they work 3D printers? These machines print or "build" an object layer by layer with a printable material, usually resin. As mentioned above, a critical factor for the success of 3D printing in orthodontics is its dimensional accuracy, especially when applications involve precise tooth movement. Among the various printing technologies, stereolithography (SLA) and digital light processing (DLP) are the main types of printers currently used by orthodontists. Many factors throughout the digital workflow can affect the fidelity of the printed models, including the accuracy of the digital model obtained with the intraoral scanner.

The DLP printers are the most widely used in orthodontics for several reasons: their printing speed is faster than SLA, it is easier to achieve good print quality and there is a wide variety of biocompatible materials for 3D printing with DLP.

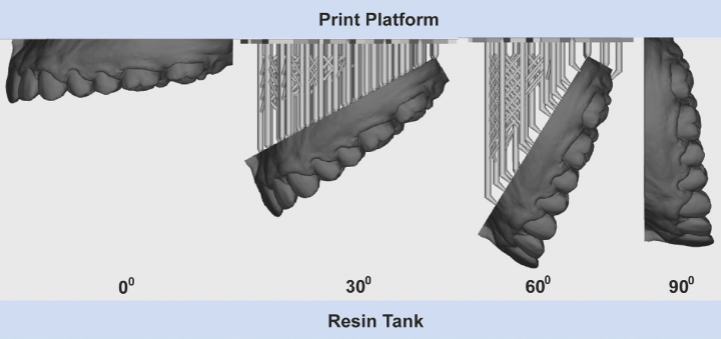

Once we have our 3D printer... What do we do now? It's time to print the models. At this point, we are going to analyse whether there is an "ideal" way to prepare them for printing. Some studies have analysed the influence of the angle at which the models are oriented and its relationship with the height (thickness) of the printing layer.

The effect of angulation of the model on the accuracy of the print changes as the layer height changes and vice versa. In other words, both variables are closely related to each other. This finding is important and sets this study apart from previous studies, which evaluated both factors independently without taking into account this relationship between the variables.

The study found that the combination of an oblique impression angle of 30° or 60° and a layer thickness of 20 to 50 micrometres produced the most accurate models. However, it is important to note that the difference in accuracy between this combination and the other groups analysed in the study was clinically insignificant and no single angle or layer thickness was identified as the "best" for all situations.

That is to say, if the 3D printer is of good quality, for the applications that we can give these models in orthodontics we will not appreciate significant differences in the printing angle. Although this inclination does not affect precision very much, it can have an impact on the cost-effectiveness of the impression. The results obtained by Williams et al. demonstrate this:

- Models printed with a 45° angulation were the most cost-effective. This print configuration used 5.20 mL of resin per model, making it the most cost-effective option.

- If we changed the angulation to 30°, more resin was consumed per model, with this inclination being the most expensive option.

This variation between angulations is related to the support structures that appear when we prepare the models for printing. Depending on the orientation of the arches, more or less supports will appear, affecting the impression time and the amount of material used.

Ko J et al. Effect of build angle and layer height on the accuracy of 3-dimensional printed dental models. Am J Orthod Dentofacial Orthop 2021;160:451-8.

Williams A et al. Effect of print angulation on the accuracy and precision of 3D-printed orthodontic retainers. Am J Orthod Dentofacial Orthop 2022;161:133-9

Share this post:

Other entries

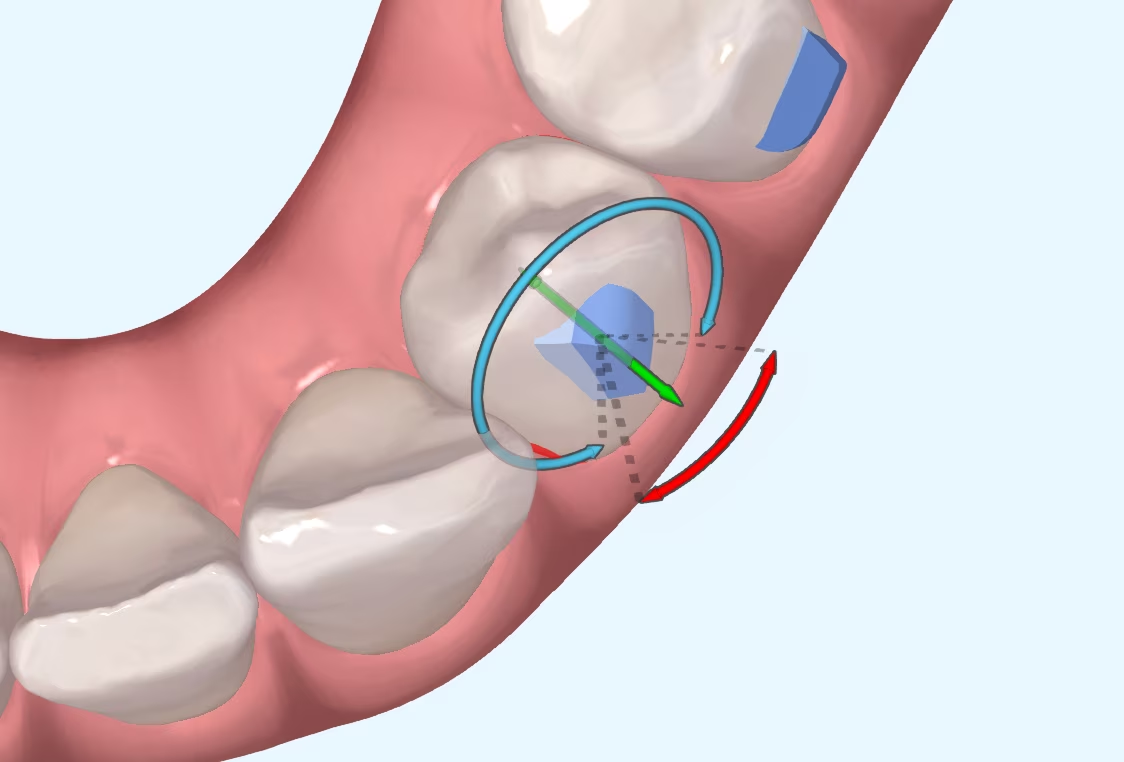

Which attachments are better for premolar rotation?

I suppose many of you are familiar with the myth of Achilles, the Greek hero who was immersed as a child in the River Styx by his mother in order to make him

Has CBCT been a step forward in dentistry?

What is CBCT? CBCT is a medical imaging technique that uses a special type of computed tomography (CT) scan to obtain three-dimensional images.

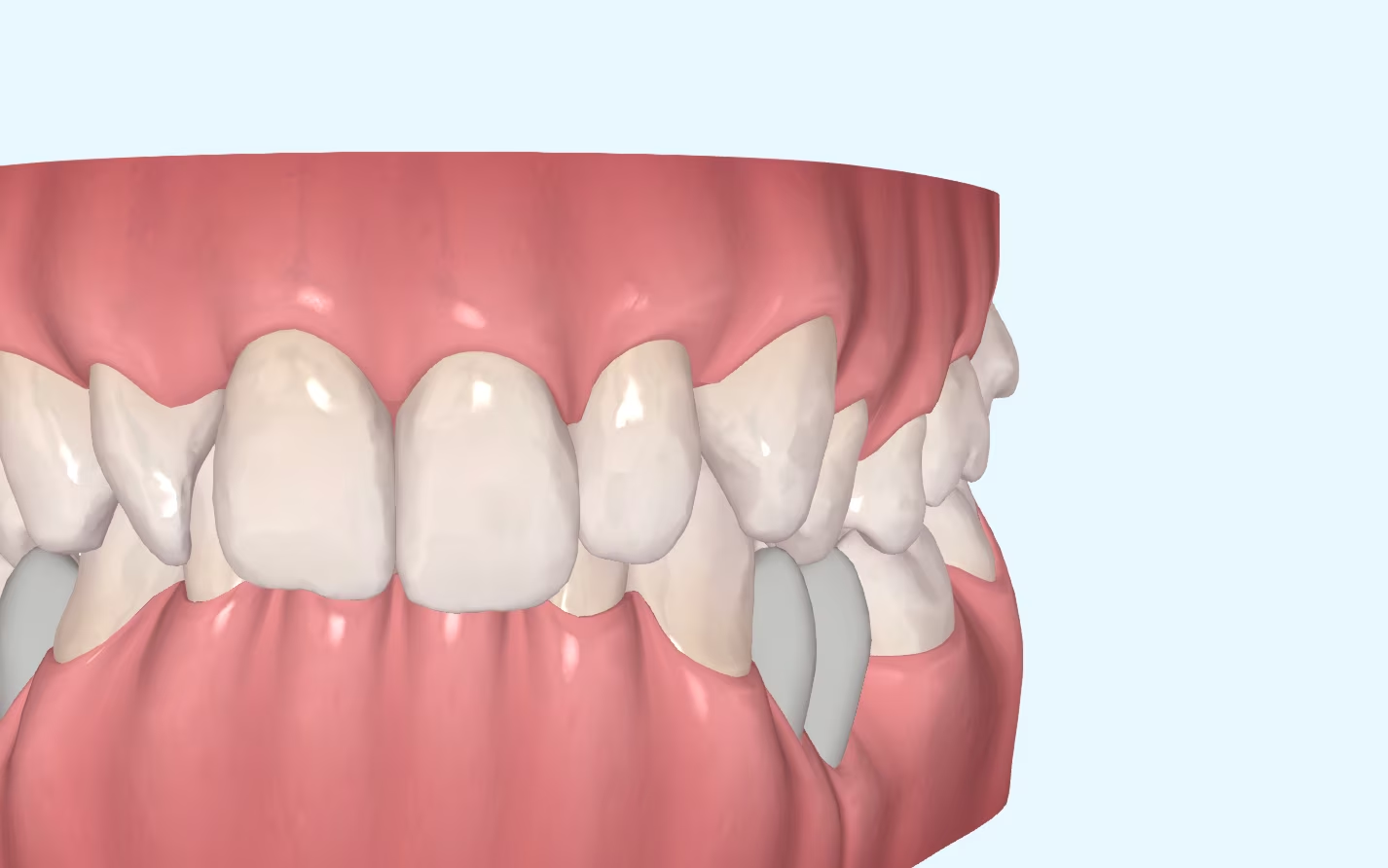

Mastering the Overbite: Strategies and Challenges:

Challenges of Overbite In the more than 20 years that we have been working with invisible orthodontics, we have gone from considering some malocclusions "impossible" to daring to

Are we aware of what we are doing?

It is not a question to make us feel guilty. It is only a question that invites us to reflect, to think about the impact we can have in

MARPE: Is there an age limit for placement?

Introduction: Understanding Maxillary Compression Maxillary compression is a relatively common problem seen in our daily practice. This osseodental discrepancy that presents the